R&D

Product Development Workflow

Key Equipment

Materials

Quality Assurance

Pre-Production Planning

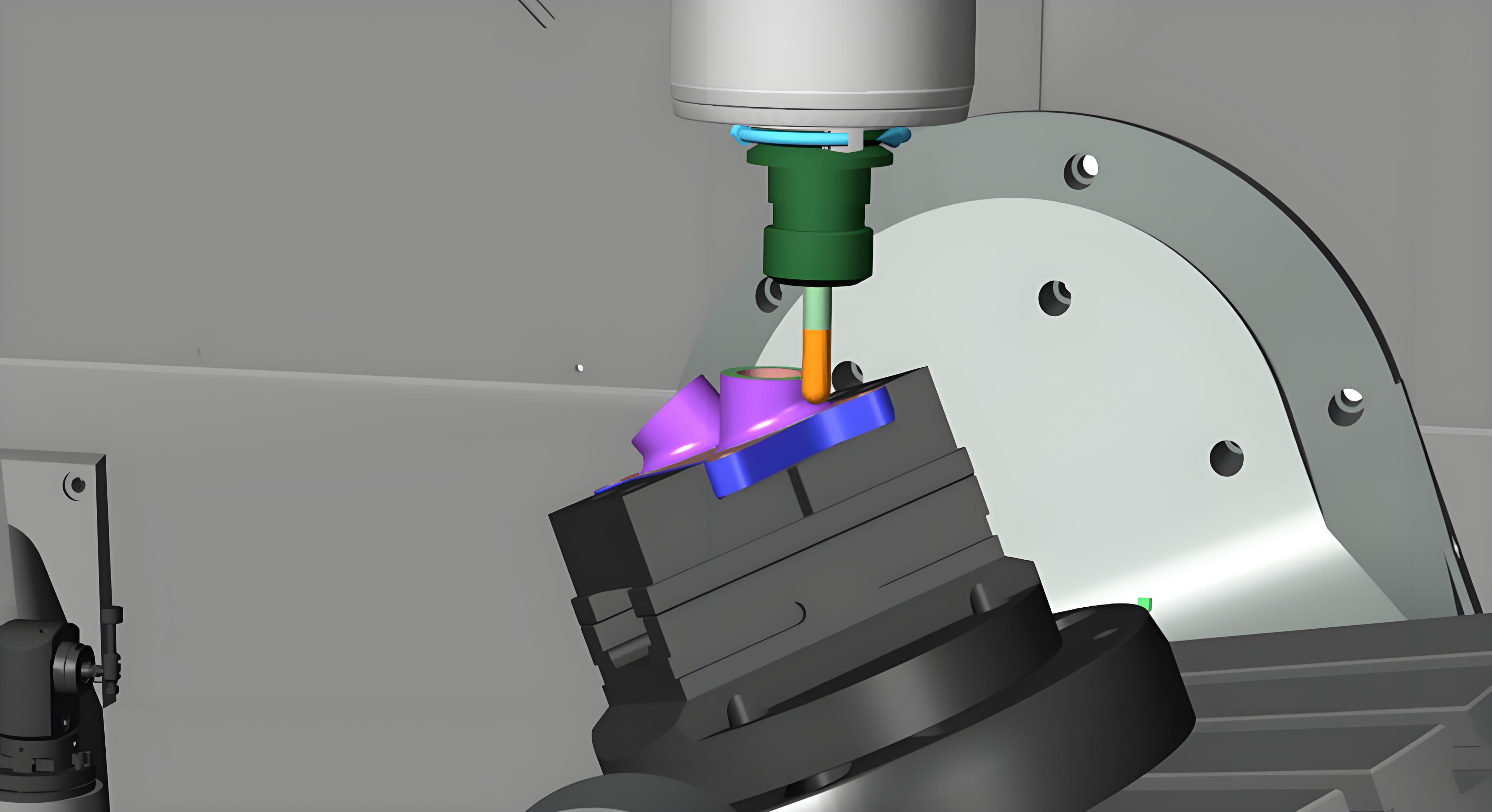

01/Simulation:

Use MAGMA for casting simulations and VERICUT for machining parameter validation.

02/New Product Development:

Refine technical data via trial production to ensure mass production stability.

Production Process Control

01/Traceability:

Unique codes track products throughout casting, machining, and post-processing.

02/Automated Data Transfer:

Networked systems ensure seamless data flow to equipment.

03/In-Process Inspection:

Automated probing detects deviations in clamping, dimensions, or precision.

Product Testing

01/X-ray Flaw Detection:

Identify internal defects like cracks, voids, or inclusions in castings.

02/CMM (Coordinate Measuring Machine):

Verify geometric tolerances and dimensional accuracy.

To Know More, Please contact us

* Full name:

* Phone:

* Company:

* Email:

* Content :

* Verification code:

Replace